The current sensor is a current detection device that can detect the information of the measured current and convert it into a standard voltage or current signal in proportion to meet the requirements of information transmission, processing, storage, display, recording and control.

Current sensor classification

Precision resistor

Also called shunt, as a common current detection component, it has the advantages of high accuracy, good linearity and high temperature stability. It is often used in small current DC applications. For AC applications, it needs to be used with a linear optocoupler. Since the shunt is directly connected in series in the circuit, it suffers from insertion loss and heat generation problems. Therefore, non-insertion product solutions are often used for high current applications.

Current Transformer

Using the different turns ratios of the primary and secondary sides to detect current signals can only be used to detect AC signals. It has the advantages of low cost, high accuracy, and simple structure.

Hall current sensor

The Hall effect is the deflection of moving charged particles in a magnetic field caused by the Loren magnet force. This deflection leads to the accumulation of positive and negative charges in the direction perpendicular to the current and magnetic field, thereby forming a transverse electric field, which amplifies the signal. Processing means converting the required signal into an output that meets the standard. Therefore, the Hall effect can be used to realize non-contact current detection, which has the advantages of no insertion loss, isolation, high detection accuracy, and simple structural circuit.

Open Loop Current Sensor

The electromagnetic signal generated by the primary current is converted into a voltage signal and output through the amplifier. There are chip-type products for small current detection and modular types for large current detection.

Closed Loop Current Sensor

There is a secondary coil on the magnetic core. When current flows through the primary side, the compensation flux generated by the secondary line current is equal to the magnetic flux generated by the primary current Ip and has an opposite direction, making the total magnetic flux in the core zero. The secondary side compensation current generated by the Hall device and the auxiliary circuit accurately reflects the size of the primary side current, and the size of the primary side current is related to the coil turns ratio.

Closed-loop current sensors have the advantages of high accuracy, good linearity, small magnetic offset, and good dynamic performance. However, the cost is relatively high and the power loss is large.

Fluxgate current sensor

Similar to the Hall current sensor, the current signal is detected by detecting the size of the magnetic flux in the air gap, except that the sensing element in the air gap becomes a fluxgate probe.

The following is a comparison of several commonly used current sensors:

Magnetoresistive current sensor

The development of magnetoresistive technology has further expanded the sensing elements of current sensors. Among them, the development of anisotropic magnetoresistance (AMR), giant magnetoresistance (GMR) and tunnel magnetoresistance (TMR) technology has enabled current sensors to achieve higher accuracy and With better temperature stability and higher bandwidth, the current finished products are mainly chip-type current detection products.

The phenomenon that the resistance of a substance changes under a certain magnetic field is called the "magnetoresistance effect". Magnetic metals and alloy materials generally have this magnetoresistance phenomenon. Under normal circumstances, the resistivity of a substance only decreases slightly in a magnetic field; Under certain conditions, the resistivity decreases to a considerable extent, which is about 10 times higher than the magnetoresistance value of ordinary magnetic metals and alloy materials, which is called the "giant magnetoresistance effect" (GMR).

With the deepening of research on the GMR effect, the TMR effect has begun to attract people's attention. Although metal multilayer films can produce high GMR values, the strong antiferromagnetic coupling effect results in a high saturation field and low magnetic field sensitivity, thus limiting the practical application of the GMR effect. In magnetic tunnel junctions (MTJs), there is no or basically no interlayer coupling between the two ferromagnetic layers. Only a small external magnetic field is needed to reverse the magnetization direction of one of the ferromagnetic layers, thereby achieving tunnel resistance. huge changes, so MTJs have much higher magnetic field sensitivity than metal multilayer films. At the same time, the structure of MTJs itself has high resistivity, low energy consumption, and stable performance. Therefore, MTJs have unparalleled advantages whether used as read heads, various sensors, or magnetic random access memories (MRAM). Their application prospects are very promising, and have attracted great attention from research groups around the world.

Introduction to precision resistors

The difference between ordinary resistors and precision resistors is mainly based on the resistance error, resistance value and temperature coefficient. For resistors with a resistance value above 1Ω (ohms), resistors with a resistance error within ±0.5% compared to the marked resistance value can be called precision resistors. Higher precision ones can achieve an accuracy of 0.01%, which is what electronic engineers call it. With an accuracy of one ten thousandth, this type of resistor is generally a thin film resistor, and resistors using this material can generally meet the production process requirements. The precision of ordinary series of resistors with a resistance of 1Ω or above is above ±5%. The most common resistors in electronic products are resistors with a precision of 5%, which do not belong to the precision resistance range.

Resistors with a resistance value below 1Ω can generally achieve a precision within ±1%, and are considered to be in the category of precision resistors. Because the resistance value base is very small, even if the error is 1%, the actual resistance value error is already very small. Higher precision can be achieved within ±0.5%, but the process requirements and technical requirements are higher.

Precision resistors are divided by material

There are several types of metal film precision resistors, wirewound precision resistors and metal foil precision resistors. The accuracy of metal film precision resistors is higher, but the resistance temperature coefficient and distribution parameter index are slightly lower; the resistance accuracy and temperature coefficient index of wire-wound precision resistors are very high, but the distribution parameter index is low; the accuracy, The temperature coefficient of resistance and distribution parameters are very high: the accuracy can reach 10-6, the temperature coefficient can reach ±0.3×10-6/℃, the distributed capacitance can be lower than 0.5pF, and the distributed inductance can be lower than 0.1μH. Since the prices of the above three types of precision resistors increase with their performance, they should be reasonably selected according to the actual situation in the application.

Core parameters of precision resistors

Resistance value and error: It is usually low resistance to reduce the power loss of the circuit. Its resistance value accuracy directly affects the measurement accuracy, usually 0.5% and 1%.

Temperature drift coefficient: As the temperature rises, the resistance value will also increase accordingly, that is, the positive temperature coefficient. At this time, the temperature drift coefficient will also be directly superimposed on the measurement accuracy error, so the lower the temperature coefficient, the better the performance.

Power: that is, the performance of heat dissipation capacity. Under the same resistance value, the greater the power, the greater the current carrying capacity. At the same time, it is closely related to the size of its layout or connecting terminals. The stronger the heat dissipation capacity of the external circuit, the lower the corresponding thermal resistance. The flow capacity is also improved accordingly.

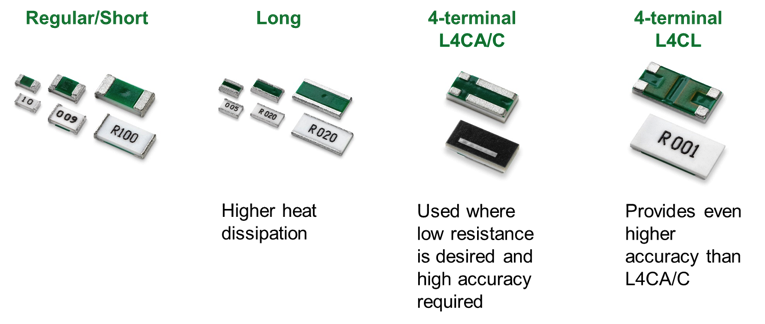

The voltage measurement position is also a factor that affects the accuracy of precision resistors. Precision resistors usually have a body and terminals. The closer to the body, the higher the accuracy. Therefore, 4-wire precision resistors can be used for applications that require high measurement accuracy.

Precision resistor comparison: There are two types of substrates: ceramic and epoxy resin. Ceramic has better heat dissipation ability, but the body will be thicker.

Comparison between metal foil and metal sheet: Both can achieve high precision and low temperature drift. Metal foil can achieve small size and wide resistance range, and metal sheet can achieve greater power.

.jpg)